Wood Underlay & Laminate Underlay Solutions

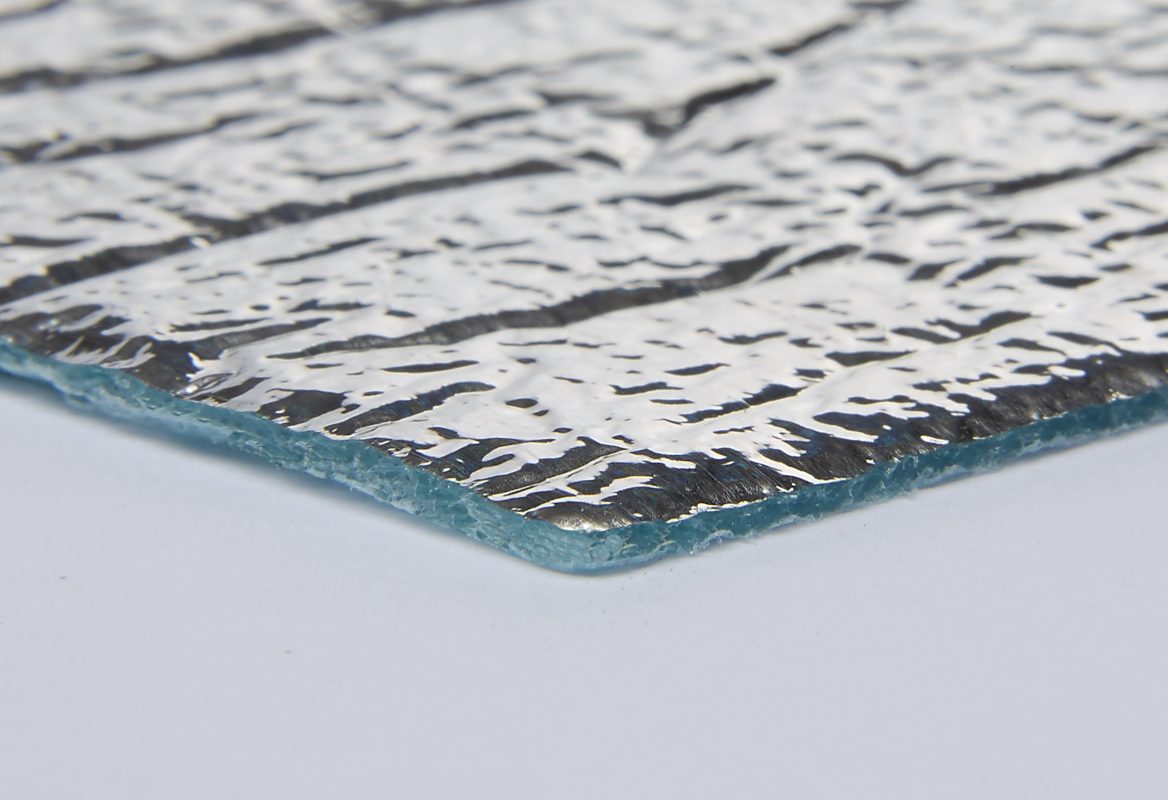

Wood and Laminate Underlay provides a supportive layer between your subfloor and your flooring — in this case, wooden floors or laminate planks. Acting as a buffer, it offers numerous benefits, from extending your floor’s lifespan and providing thermal insulation to adding a moisture barrier (essential for protecting wood from damp) and enhancing soundproofing.

Our wood and laminate underlays are compatible with a wide range of laminate and engineered wood flooring options — so you’re sure to find the right solution below.

Looking for carpet underlay instead? Check out our underlays for carpet flooring.

Explore our full range of Wood and Laminate Flooring Underlay, along with helpful FAQs below.

Not sure which underlay you need? No Problem – Use our Traffilay System for guidance. With so many options available (foam, rubber, laminate, carpet, and wood underlays, among others), finding the perfect one can feel overwhelming. Our Traffilay System will guide you to the right choice based on your flooring type and performance requirements.

Take a look at the Technical Specifications for Wood Underlayin our directory at the top of the page!

What is the difference between laminate underlay and wood underlay?

All flooring underlays serve a similar purpose: to enhance performance and comfort.

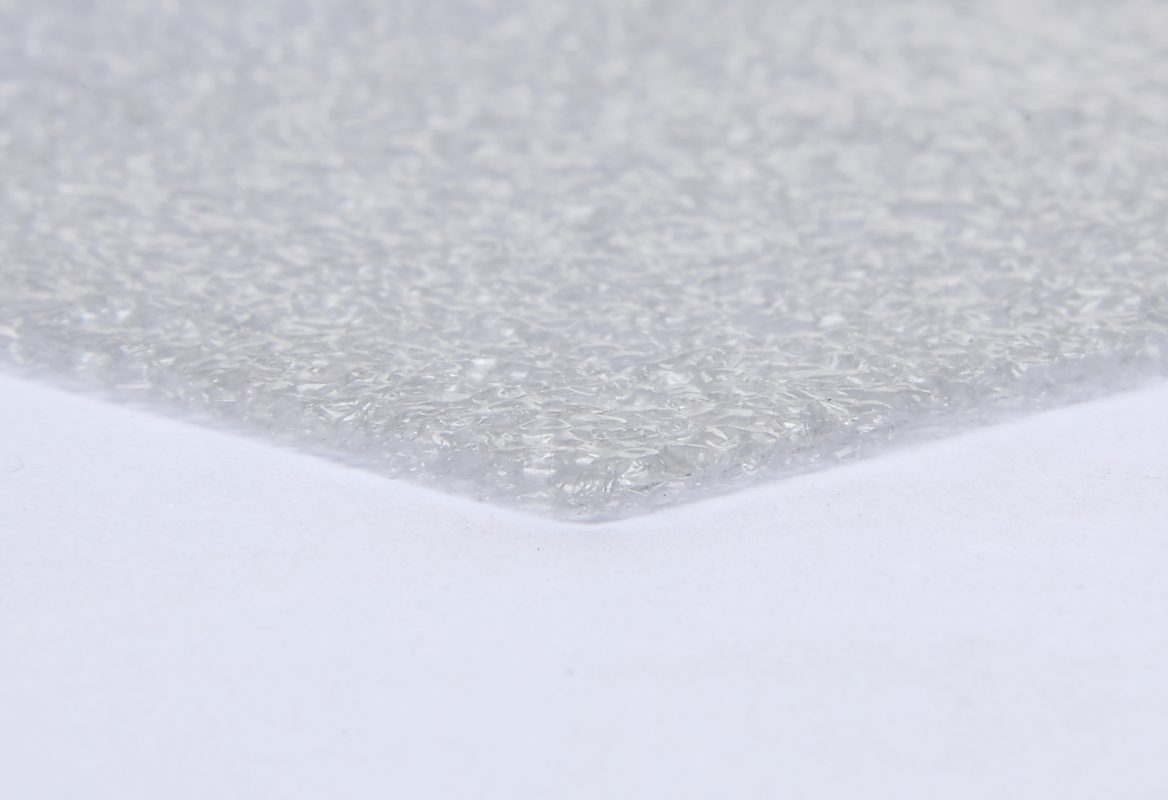

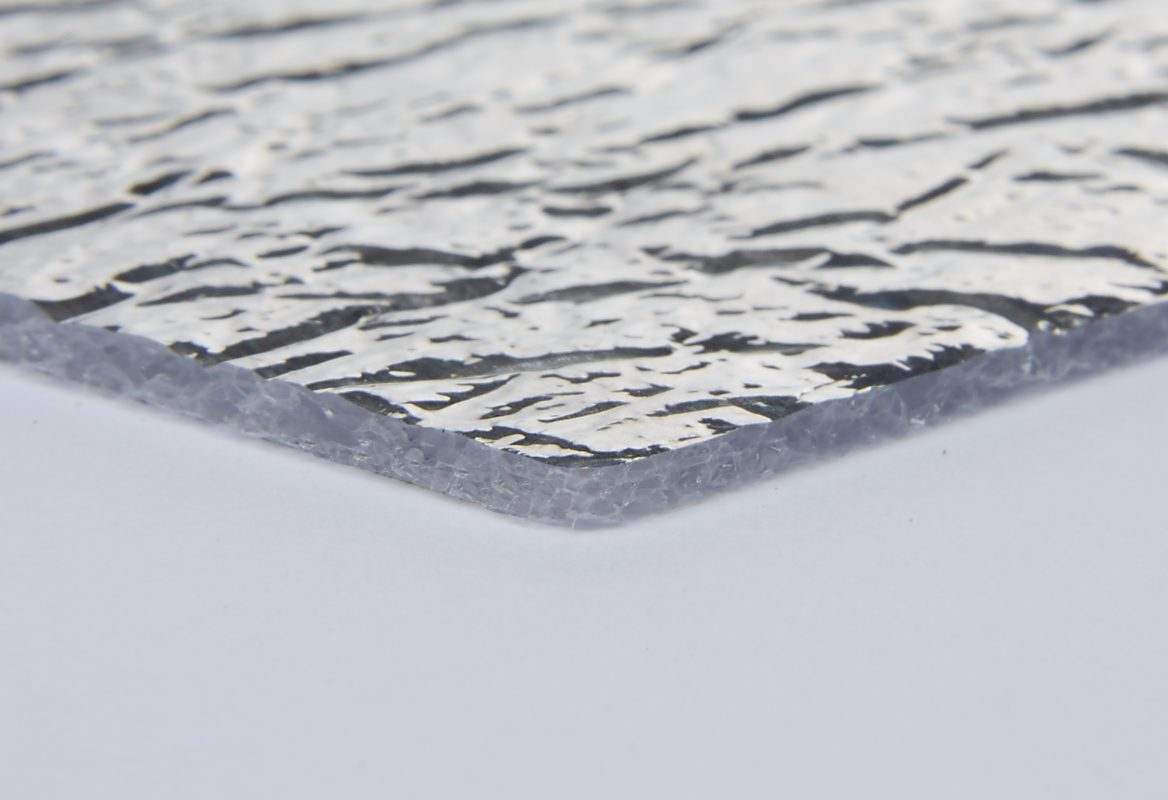

- Laminate Underlay – Typically made from foam or wood fibres, laminate underlay is designed for use with click-lock laminate flooring installations. It often includes an integrated moisture barrier or damp-proof membrane — essential for protecting laminate floors, which are especially vulnerable to moisture.

- Wood Underlay – Wood underlay may be made from cork, rubber, or wood fibres. It generally prioritises soundproofing and comfort through added thickness and cushioning. Many options also have a higher tog rating (thermal resistance) to help combat cold floors — something to consider if you have or plan to install underfloor heating.

You can find other underlay benefits for laminate and wood flooring too. Looking to enhance thermal insulation for a warmer floor? We have an underlay for that. From noise reduction to moisture protection, to helping level out slightly uneven floors, installing underlay for laminate or wood flooring can bring a range of benefits and features. Your only job? Selecting the best one for your floor's needs.

How Do You Place An Order?

There are multiple different ways to place an order with us. Whether by phone (0151 495 3434), registered customers can use our online trade-only portal (trade.qaflooringsolutions.com), or email ([email protected]), we are geared to provide you with what your customers need.

We offer a standard 2-3 day delivery service with next day delivery available if required. We also offer a range of delivery options, from timed deliveries to home address and site drops so you can be sure that you get your goods on time!

Our delivery options:

- FREE 2-3 day delivery on all orders over £450

- Minimum order value £450

- Standard lead time 2-3 days

- Under minimum order £45

- Next day or specific delivery £45

- Delivery to building site / home address £48

- AM or specific time £50

- Saturday / same day P.O.A.

- All orders to Scotland & Ireland FREE delivery over £5k.

- Under £5k delivery charge P.O.A

- Outside mainland UK / export P.O.A.

- Discount on Customer Collections 5%

Yes — several of our underlays are designed to perform efficiently with underfloor heating systems.

Both QuickTherm Underlay and QuickTherm Vapour Underlay feature a unique perforated design and ultra-low tog values that allow heat to transfer effectively. This ensures your underfloor heating system runs efficiently and uses less energy.

These thermal underlays are ideal for use with wood and laminate flooring in spaces where warmth is essential — particularly over cold concrete subfloors.

In essence, the underlay sits between your flooring and the underfloor heating system, distributing heat evenly across the surface.

We will split the following section between wood/laminate flooring requirements.

Wood Flooring

- Subfloor Type – Concrete subfloors require a moisture barrier, as trapped moisture can damage wood over time. Wood subfloors generally require less protection.

- Thickness – Excessive underlay thickness can cause instability — see the next FAQ section for more details.

- Room Use – In high-traffic areas, you should opt for a more dense underlay for added durability.

- Sound Reduction – Wood floors can be noisy, so underlays designed for soundproofing are particularly effective.

Laminate Flooring Underlay

- Subfloor Type – Again, concrete will almost always require a moisture barrier.

- Thickness – Choose a firm, supportive underlay — laminate floors need stability.

- Room Use – Dense underlays are recommended for high-traffic areas to protect your laminate from wear and tear.

Don’t forget to purchase the correct accessories to ensure your underlay joins securely with the flooring. Always adhere to fitting requirements outlined by manufacturers.

| Flooring Type | Recommended Thickness Range | Considerations |

| Laminate Flooring | 2mm – 7mm depending on type and use | Sound Absorption: Thicker underlays generally offer better sound insulation.

Cushioning: Added cushioning enhances comfort. However, excess thickness can cause instability or damage. Subfloor Condition: Thicker underlays, such as FineFloor FibreBoard (up to 7mm), can smooth out imperfections in the subfloor. |

| Wood Flooring (Solid) | Typically thinner | Stability: Exceeding recommended thickness can cause instability and potential damage to solid wood flooring.

Type of Wood: Some softer wood species may benefit from slightly thicker underlay for additional support. |

| Wood Flooring (Engineered) | More flexibility than solid wood | Manufacturer’s Recommendations: These are still paramount. Engineered wood may have greater thickness allowances compared to solid wood.

Room Location: Upper-level rooms might benefit from underlay providing sound reduction to lower levels. |

Whilst it’s difficult to say exactly how long a wood or laminate underlay is likely to last as all installations and traffic use differ, the following is a guide:

Typical lifespan ranges:

- Foam laminate underlays: usually 5–10 years (budget types)

- High-density foam, rubber, or fibreboard underlays: often 10–20 years

- Premium cork or rubber underlays (especially under engineered wood): can last 20–25 years or more

The lifespan depends heavily on:

- The quality of the underlay material

- The flooring type and traffic levels

- Moisture exposure and installation quality

Wood and laminate underlays tend to last longer than carpet underlays, which experience greater compression from daily use. Since wood and laminate floors are harder materials, they protect the underlay more effectively. However, wood floors are more vulnerable to moisture-related issues.

On average, wood and laminate underlays last between 5 and 25 years, depending on factors such as product quality, installation, moisture levels, and overall floor maintenance.

Each renovation project requires a different approach as all people in the trade will know. It’s good to have a variety of underlays on hand to support your customers and their needs. So check out our full range today.